Comprehensive Guide to Eco-Friendly Precious Metal Recovery

Did you know that more than $60 billion worth of precious metals are discarded each year in electronic waste alone? That eye-opening statistic shows how important recycling these metals really is. Not only does it boost economic health, it also protects our environment. When we recover gold, silver, platinum, and palladium, we reduce pollution and conserve resources.

Companies like Dongsheng Metal Trading are leading the charge towards sustainability. They make sure those precious metals get reused rather than landfilled. That precious metal recycling strategy underpins green recycling and long-term sustainability.

Vital Takeaways

- More than $60 billion of precious metals end up in e-waste each year.

- Precious metal recycling reduces environmental impact and conserves resources.

- Valuable metals include gold, silver, platinum, and palladium.

- Eco-friendly recycling practices are vital for sustainable development.

- Recycling experts like Dongsheng Metal Trading lead the industry.

Exploring Precious Metals and Their Worth

Naturally scarce metallic elements called precious metals draw interest from industries and investors. Gold, silver, platinum, and palladium stand out for their distinct qualities. These include electrical conductivity, corrosion resistance, and substantial rarity. The extraction and processing of these metals require considerable resources, underscoring the importance of recycling precious metals.

The value of precious metals is influenced by market demand and the inherent qualities of each metal. Recycling precious metals plays a critical role in sustaining the supply chain. It cuts the environmental toll of mining operations. Through exhaustive recycling processes, these metals can be restored to their original state. Such efforts save limited resources and create economic gains.

Defining Precious Metals

Unique features make precious metals ideal for many uses. Economic value stems from their scarcity and innate qualities. Notable examples are:

- Au: Valued for its beauty and resistance to tarnish.

- Silver: Celebrated for its adaptability and conductivity.

- Platinum: Esteemed for its toughness and catalyst role.

- Palladium: Gaining traction in cars and electronics.

Why Recycle Precious Metals?

Recovering precious metals plays a crucial role in sustainability. It preserves resources and lessens the environmental cost of mining. Here are some benefits:

- Reduction of environmental degradation caused by mining operations.

- Energy needs are far lower than mining virgin ore.

- Feeding materials back into the production loop.

- Opportunity for profit by recovering valuable metals.

The Importance of Precious Metal Recycling

Metal recycling brings both green and economic gains. Pointing out these perks shows how to shrink our eco-impact. Plus, it spurs economic development and steadiness.

Environmental Benefits

Green gains from metal recycling are huge. By reclaiming metals from discarded electronics and industrial scrap, we cut down on landfill waste. It curbs mining demand and preserves nature.

It curtails mining’s damage, like habitat loss and toxins. Focusing on recycling precious metals helps us strive for a more sustainable future.

Financial Gains

Economic upsides of recycling stand out equally. Using reclaimed metals trims manufacturing budgets. This allows industries to use reclaimed metals instead of new ones.

It produces recycling-sector employment and strengthens markets with growing recycled-metal needs. Harnessing these gains helps firms improve their bottom line. They add to a more sustainable marketplace.

How Precious Metals are Recycled

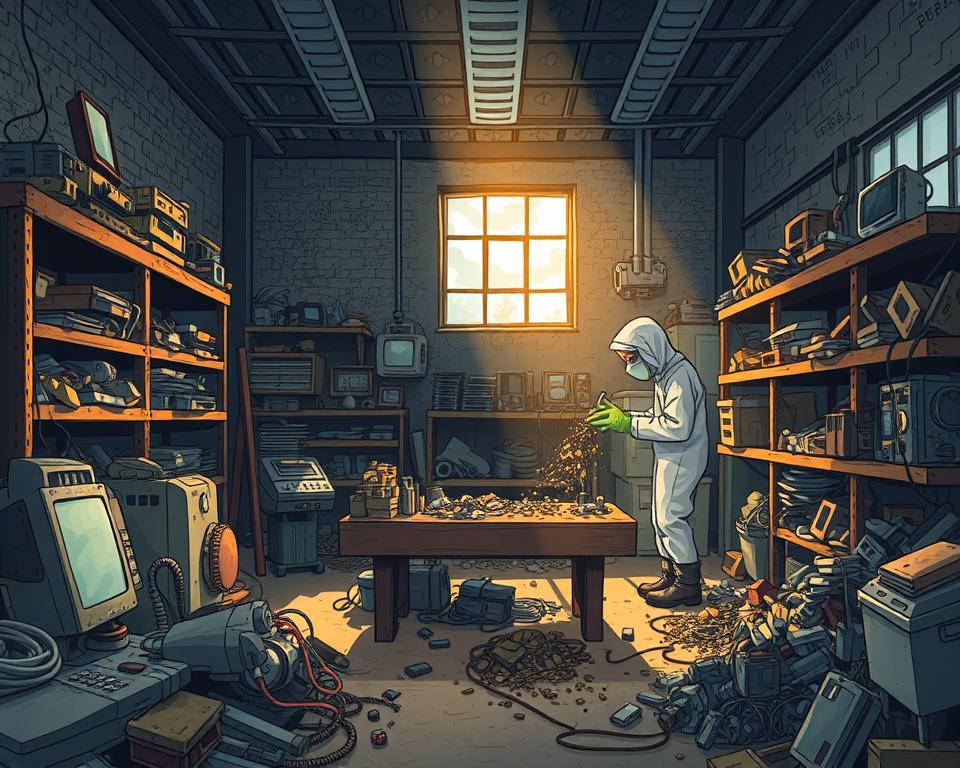

Metal recycling demands a multi-stage process to optimize recovery. It starts with collecting metals from various sources like discarded electronics, jewelry, and industrial scraps. They are sorted, decontaminated, and analyzed to gauge composition and value.

The Precious Metal Recycling Process

Such a methodical process ensures efficient recovery. All stages focus on boosting metal yield. Sorting divides metals by kind and grade. Decontamination eliminates residues that block recovery. Testing measures metal content to select proper recycling methods.

Metal Separation Techniques

Cutting-edge processes boost precious-metal recovery. Thermal reduction, using high temperatures to separate metals from ores, is a key method. Molten refining and wet-chemistry steps handle finer separations. Companies like Dongsheng Metal Trading use these methods to boost efficiency and maximize returns in the precious metal recycling process.

Recyclable Precious Metals

Recycling is vital for the environment and for recovering valuable materials. Numerous precious metals lend themselves to recycling, serving both business and environment. Awareness of recyclable metals guides consumers and companies.

Recycling Gold, Silver & Platinum

Familiar precious metals include gold, silver, and platinum. They’re found in jewelry, coins, and industrial uses. Gold recovery is widespread because of its worth and need. Silver’s role in cameras, electronics, and solar energy makes its recycling vital.

Platinum, while rarer, finds value in catalytic converters.

Rare Metals in Electronics

E-waste metals present special recovery opportunities. Gadgets—from phones to laptops—house palladium, indium, and more. Reclaiming them cuts e-waste and recovers key resources.

It’s crucial to recover these electronic metals. Businesses work to reduce scrap and upscale resource recovery.

Industry Benefits of Precious Metal Recovery

Metal recovery underpins major sectors by supplying reclaimed resources sustainably. Device manufacturing in electronics profits hugely from recovered metals. The aerospace and medical fields use precious metals in essential applications. Examining industry recovery uncovers eco- and economic advantages.

E-Waste Sector

Because devices abound with metals, electronics tops recycling efforts. Quick device turnover spawns more electronic scrap. Thus, recycling gold, silver, and palladium efficiently becomes vital. That saves resources and cuts mining carbon footprints.

Companies are increasingly focusing on recycling to meet global sustainability and waste reduction goals. That change bolsters resource saving and ecosafety.

Aerospace and Medical Equipment

Aerospace metal recycling is vital for the aerospace and medical industries, which rely on precious metals for critical components. Alloys prized for strength and anti-corrosion make up flight and medical components. Metal recovery slashes expenses and ensures eco-compliance.

These sectors know green recovery eases resource shortages. Plus, it boosts efficiency, cementing recycling as a sustainability strategy.

Finding Precious Metal Recycling Companies

Choosing reputable metal recyclers is vital for success. It’s wise to ask important questions to understand their operations. Pricing models and processes make a big difference. By comparing services, you can see what each company offers and make a smart choice.

Questions to Ask Recycling Companies

- What certifications do you hold regarding precious metal recovery?

- How do you process various precious metals?

- Which recovery percentages do you achieve for each metal?

- Can you detail your fees and any surcharges?

- Can you share feedback from past customers?

Service & Price Comparison

You must evaluate services side-by-side to pick the right recycler. Use a table to line up these factors:

| Company Name | Recovery Rate (%) | Processing Fee ($) | Turnaround Time (Days) |

|---|---|---|---|

| Recycling Co. A | 95 | 50 | 7 |

| Recycling Co. B | 90 | 45 | 5 |

| Recycling Co. C | 92 | 55 | 10 |

By comparing recycling services, you can find the best recycler for your needs. It guarantees maximum value and compliance.

Recycling Precious Metals: A Green Guide

Grasping recycler workflows is essential for metal recovery. They oversee everything from scrap pickup to refining. This ensures maximum efficiency and value from metals.

Behind the Scenes of Recycling

Recyclers use advanced methods for metal recycling, including testing, separation, and refining. First, they gather scrap from multiple origins. Afterwards, they apply refined techniques to isolate each metal. In the last stage, precious metals are refined to purity.

It optimizes yield while advancing environmental goals. It’s a critical step towards sustainable development.

Choosing the Right Recycler for Your Needs

You’ll want to weigh several factors in your choice. First, look at their environmental practices. In today’s market, a commitment to sustainability is essential. Next, review their service range—from pickup to refining.

Your budget will influence your choice. Get quotes to compare different options. Experts like Dongsheng Metal Trading provide industry-specific offerings. They are a reliable choice for specific recycling needs.

Pick the Right Facility

Recycling centers play a key role in sustainability and waste control. There are specialized centers for different metals and materials. Understanding these facilities improves access to recyclers and their services. That supports firms and ecosystems alike.

Recycling Center Types

Metal recycling facilities vary widely in their operations. Some focus on precious metals, while others handle a wide range of materials. Here are a few common types:

- Scrap yards process a broad mix of metal types.

- Precious Metal Recovery Companies: With a focus on high-value materials such as gold, silver, and platinum, these companies offer refined processing techniques.

- E-waste hubs target valuable metals inside tech devices.

Facility Access Factors

Accessibility to recyclers is key for efficient metal recovery. Firms need to plan transport logistics. Here are some factors that influence access:

| Factor | Description |

|---|---|

| Distance | Nearby recyclers reduce haul time and expense. |

| Partnerships | Having established relationships with local recyclers can enhance efficiency in recycling processes. |

| Service Range | Understanding the specific services of metal recycling facilities helps businesses select appropriate partners. |

Choosing appropriate centers and easy access drives recovery efficiency.

E-Waste Recycling & Metal Recovery

Electronic waste is a pressing issue in today’s world, causing environmental harm. Many e-waste items hold recoverable precious metals. This highlights the importance of seeing e-waste as a valuable resource.

Electronic Precious Metals

Gadgets harbor small quantities of precious metals. You’ll find them in components such as:

- Circuit boards

- Connectors and ports

- Capacitors and resistors

- Battery terminals

Even everyday items like smartphones, laptops, and TVs are filled with these metals. By recycling, we retrieve and reuse these valuable elements.

The Importance of E-Waste Recycling

E-waste recycling is vital for both environmental protection and resource recovery. That cuts landfill volume and conserves resources. The benefits of recycling e-waste metals are clear:

- It lowers pollution risks tied to discarded electronics

- It curbs carbon footprints with sustainable recycling

- It fuels a circular economy by feeding materials back into manufacturing

Promoting e-waste recovery advances resource stewardship. It secures a healthier planet for tomorrow’s children.

What’s Next in Metal Recycling?

The field of precious metal recycling is undergoing a transformation, driven by technological progress and a surge in sustainability efforts. With resource conservation rising, recyclers are innovating. Adopting fresh techniques, they’re shaping tomorrow’s recycling.

Green Recycling Trends

Current trends in sustainable recycling focus on reducing waste and minimizing environmental impact. Firms now use bio-packaging and low-energy methods. That evolution supports global green targets and fosters industry responsibility.

Cutting-Edge Recovery Methods

Breakthroughs in recovery boost metal recycling yields. Automated sorters and hydrometallurgy ramp up yield. They ramp up yields and shrink eco-footprints, advancing metal recycling.

How to Start Your Own Precious Metal Recycling Business

Building a metal recycling enterprise calls for thorough planning and industry knowledge. Leaders should map out steps, secure compliance, and set firm roots. That means in-depth market analysis and client identification. Securing licenses and legal compliance is crucial for long-term viability.

Business Setup Steps

Setting up a precious metal recycling venture requires several essential steps:

- Research the market to grasp demand and competition.

- Create a comprehensive plan with objectives and tactics.

- Purchase the right gear for your recycling operations.

- Raise startup funds through financing or investors.

- Get all required permits and licenses.

- Launch marketing to attract clientele.

Compliance and Certifications

Knowing regulatory requirements is vital for a recycling startup. Adherence to environmental regulations ensures your operation is safe and sustainable. Key considerations include:

- Getting licensed by appropriate agencies.

- Following all levels of waste and recycling regulations.

- Certifying employee knowledge of safety and handling rules.

Wrapping It Up

Precious metal recycling is essential for preserving natural resources and improving environmental health. It helps people and companies cut waste’s ecological toll. Recovered metals curb mining and fuel green-job growth in recycling.

Beyond green gains, recycling yields financial perks. Teaming with Dongsheng Metal Trading secures sustainable methods. Such alliances reinforce the circular economy for all stakeholders.

A sustainable tomorrow hinges on our joint metal-recycling efforts. Growing awareness can lead to a society that values responsible consumption and environmental care. Implementing these measures supports us today and safeguards future generations.