Optimise with Fiber Secondary Coating Line Tech

Welcome to our article on optimizing fiber optic production with fiber secondary coating line technology. In today’s fast-paced and interconnected world, reliable and efficient communication networks are essential. Fiber optic cables play an important role in transmitting data quickly and securely over long distances. To be sure the performance and sturdiness of these cables, secondary coating technology is of paramount importance.

Secondary coating refers back to the procedure for applying a protective layer on the delicate glass fiber core of the fiber optic cable. This coating acts as a shield, safeguarding the core from external elements and potential damage. Moreover, it helps maintain optimal performance in harsh environments, preventing attenuation and ensuring high-quality signal transmission.

In this post, we shall explore the significance of fiber draw tower cables and explore the world of fiber secondary coating line technology. We are going to discuss the key characteristics of effective coating lines, advancements in fiber optic cable coating solutions, and methods for maximizing production efficiency. Furthermore, we’ll emphasize the importance of quality control through the coating process and offer insights in to the mechanics and functionality of fiber draw towers.

Key Takeaways:

- Secondary coating is vital for protecting the fragile glass fiber core of fiber optic cables.

- It helps maintain optimal performance in harsh environments and sustains optimal optical properties.

- Fiber secondary coating line technology can be used inside the manufacturing procedure for fiber optic cables.

- Advancements in coating solutions include innovative materials and new coating techniques.

- Maximizing production efficiency requires high-speed secondary coating and effective quality control.

The Significance of Secondary Coating in Fiber Optic Cables

Inside the world of fiber optic cables, secondary coating plays a crucial role in ensuring the performance and longevity of those advanced communication systems. By protecting the fragile glass fiber core, secondary coating safeguards the integrity in the signal transmission and maintains optimal optical properties.

Protecting the Glass Fiber Core

The glass fiber core is the heart of the fiber optic cable, in charge of transmitting light signals over long distances. However, the glass fibers are incredibly sensitive and can be easily damaged by external factors such as moisture, mechanical stress, or chemical exposure. Here is where secondary coating is necessary.

Secondary coating gives an additional layer of protection around the glass fiber core, shielding it from potential harm. This protective layer behaves as a barrier, preventing moisture ingress and physical damage, ensuring the longevity and longevity of the fiber optic cable.

Maintaining Performance in Harsh Environments

Fiber optic cables are frequently deployed in harsh environments, including underground installations, outdoor settings, and industrial applications. In these demanding conditions, maintaining optimal performance becomes paramount.

Secondary coating in fiber optic cables enhances their effectiveness against temperature changes, humidity, and contact with chemicals. This added protection helps to ensure that the cables can withstand extreme climate conditions, corrosive substances, and other environmental factors, without compromising signal transmission quality or efficiency.

Sustaining Optimal Optical Properties

Optical properties such as low attenuation (signal loss) and high signal transmission quality are critical for fiber optic cables to operate effectively. The secondary coating in fiber optic cables plays a crucial role in sustaining these optical properties.

The secondary coating material is carefully selected to reduce signal loss and maintain optimal light transmission. By reducing signal attenuation, the secondary coating helps to make sure that the fiber optic cable maintains high-quality signal integrity, leading to reliable and efficient communication.

In As a Final Point, secondary coating in fiber optic cables is not just an enhancement but a necessity in today’s advanced communication systems. It works as a protective shield, safeguarding the glass fiber core, maintaining performance in harsh environments, and sustaining optimal optical properties.

Guide To Fiber Secondary Coating Line Technology

In the world of fiber optic cable manufacturing, using advanced technology is crucial to ensure the manufacture of high-quality and reliable cables. One such technology that plays an important role inside the manufacturing process is fiber secondary coating line technology. This innovative technology involves the use of a secondary coating towards the fiber optic cables, providing additional protection and enhancing their performance.

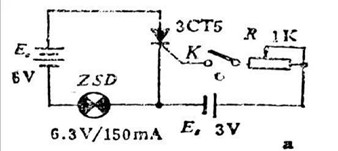

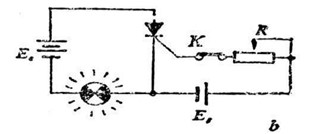

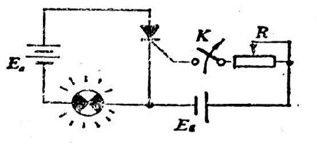

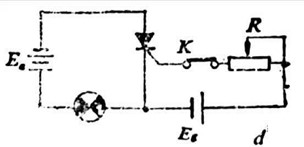

The secondary coating equipment utilized in fiber secondary coating line technology contains state-of-the-art machinery and tools created specifically for this purpose. These equipment and machinery ensure precise and uniform application of the secondary coating, resulting in efficient and reliable cable production. They include advanced features and control systems which allow seamless operation and optimal performance through the coating process.

With fiber secondary coating line technology, manufacturers can achieve enhanced cable durability, better effectiveness against environmental factors, and improved overall cable performance. The use of this technology makes sure that fiber optic cables can withstand the difficulties of harsh conditions, which makes them ideal for a variety of applications and industries.

Advancements in Fiber Optic Cable Coating Solutions

With the ever-increasing demand for faster and much more reliable internet connections, the requirement for advanced fiber optic cable coating solutions is becoming paramount. Technological advancements have paved just how for innovative materials and new coating techniques that provide enhanced protection and improved performance for fiber optic cables. Additionally, the accessibility to custom coating systems tailored to specific cable specifications has further revolutionized the business. Let’s look into the exciting developments in fiber optic cable coating solutions and explore the advantages they offer.

Innovative Materials for Enhanced Protection

Coating materials play an important role in protecting the delicate glass fiber core of fiber optic cables from external elements and potential damage. In recent years, there has been remarkable advancements in the development of innovative materials created to provide enhanced protection. These materials offer improved resistance to mechanical stress, temperature variations, moisture, and chemical exposure, ensuring reliable performance even just in challenging environmental conditions.

New Coating Methods For Better Performance

Alongside innovative materials, new coating techniques have emerged to improve the performance and sturdiness of fiber optic cables. These techniques focus on achieving lower attenuation, higher signal transmission quality, and increased potential to deal with bending and microbending losses. Through state-of-the-art coating methods like plasma enhanced chemical vapor deposition (PECVD) and atomic layer deposition (ALD), the fiber optic coating process continues to be optimized for superior performance, ensuring reliable data transmission and minimal signal loss.

Custom Coating Systems Tailored to Cable Specifications

Every fiber optic cable project is exclusive, with specific requirements and specifications. To deal with this diversity, custom coating systems have already been developed to provide tailored solutions. These systems allow manufacturers to customize the coating process according to cable dimensions, fiber count, and specific operational needs. By integrating automated controls and monitoring systems, custom coating systems ensure precision coating thickness, uniformity, and consistency, leading to high-quality, reliable fiber optic cables that meet industry standards.

| Advancements |

Innovative Materials |

New Coating Techniques |

Custom Coating Systems |

| Enhanced protection for fiber optic cables |

Effectiveness against mechanical stress, temperature, moisture, and chemicals |

Lower attenuation, higher signal transmission quality, and increased potential to deal with bending and microbending |

Tailored solutions based on cable specifications |

| Better performance and sturdiness |

Superior protection in challenging environmental conditions |

Precision coating thickness, uniformity, and consistency |

Automated controls and monitoring systems |

Cost Efficiency in Fiber Optic Manufacturing

The manufacturing procedure of fiber optic cables could be complex and costly. However, optimizing cost efficiency is crucial for companies in this particular industry to keep competitive and profitable. By implementing the correct strategies and technologies, manufacturers is effective in reducing production costs and improve overall efficiency, ensuring long term success.

One key area where cost efficiency can be accomplished is incorporated in the fiber optic manufacturing process itself. By streamlining and optimizing the development workflow, manufacturers can eliminate unnecessary steps, minimize material waste, and lower production time. This can result in significant financial savings and improved productivity.

Another essential aspect to take into consideration is deciding on a materials and equipment utilized in the manufacturing process. Investing in high-quality yet cost-effective materials, including reliable Compact fiber unit(CFU), can lead to long-term cost savings by reduction of maintenance and replacement costs.

Furthermore, advancements in technology have led to the growth of more efficient and automated manufacturing equipment. These state-of-the-art machines can increase production throughput and accuracy while reducing labor and operating costs. By purchasing such equipment, manufacturers can achieve higher output levels and improved product quality.

Additionally, implementing quality control measures at every stage from the manufacturing process may help identify and address any issues or defects early on, minimizing the potential for costly rework or product recalls. Utilizing advanced testing and inspection techniques can ensure the production of high-quality fiber optic cables that meet industry standards and customer expectations.

In Final Thoughts, cost efficiency plays a crucial role in fiber optic manufacturing. By adopting appropriate strategies, utilizing advanced technologies, and optimizing the manufacturing process, companies can achieve significant cost savings, improve overall efficiency, and maintain a competitive edge on the market.

Fiber Secondary Coating Line

In the creation of fiber optic cables, the fiber secondary coating line plays a crucial role in ensuring the ultimate cable quality and durability. Effective coating lines are necessary for protecting the delicate glass fiber core from external elements and potential damage, while also maintaining optimal optical properties.

Key Characteristics of Effective Coating Lines:

- High Precision: Effective coating lines are created with high precision to ensure accurate implementation of the secondary coating material on the fiber optic cables. This precision is vital for maintaining consistent coating thickness and avoiding defects that may compromise the cable’s performance.

- Uniform Coating Distribution: Properly designed coating lines guarantee the uniform distribution of the secondary coating material along the length of the cable. This uniformity is important for achieving optimal cable performance and preventing disadvantages or inconsistencies inside the coating.

- Controlled Cure Process: Coating lines with controlled cure processes allow for precise charge of the curing parameters, like temperature and time. This helps to ensure that the secondary coating material cures properly, resulting in a strong and durable cable.

- Flexibility: Effective coating lines are designed to handle various cable sizes and types, accommodating different production requirements. This flexibility allows manufacturers to create an array of fiber optic cables without compromising on coating quality.

- Advanced Monitoring Systems: State-of-the-art coating lines are equipped with advanced monitoring systems that continuously monitor and analyze the coating process. This permits real-time adjustments and ensures consistent coating quality throughout production.

Influence on Final Cable Quality and sturdiness:

A powerful fiber secondary coating line directly contributes to the quality and durability of the final fiber optic cable. The secondary coating works as a protective barrier, safeguarding the fragile glass fiber core from moisture, mechanical stress, along with other external factors that may jeopardize the cable’s performance. Through providing a reliable and consistent coating, effective coating lines be sure that the cable maintains its optimal optical properties, low attenuation, and high signal transmission quality.

State-of-the-Art Equipment for Reliable Processing:

To accomplish quality results, fiber secondary coating lines incorporate state-of-the-art equipment for reliable processing. These equipment are made to handle the fragile fiber optic cables with precision, ensuring accurate use of the secondary coating material. Advanced control systems and automated processes further enhance the reliability and efficiency from the coating lines, minimizing human error and optimizing production output.

| Equipment |

Function |

| Optical Fiber Pay-Off |

Provides controlled tension and unwinding from the fiber optic cable during the coating process. |

| Coating Unit |

Applies the secondary coating material to the fiber optic cable with precision, ensuring uniform distribution and controlled cure process. |

| Curing Chamber |

Creates the ideal curing conditions for that secondary coating material to harden and form a protective layer across the fiber optic cable. |

| Fiber Take-Up |

Controls the winding and tension in the fiber optic cable after the coating process is complete, ensuring an effortless and consistent cable winding. |

Comparing Compact and Full-Scale Coating Lines

When it comes to fiber optic manufacturing, selecting the best coating line is vital to ensure optimal production efficiency and quality. Two common options are compact coating lines and full-scale coating lines. Let’s compare and contrast those two types to comprehend their advantages, disadvantages, and suitability for various production requirements.

Compact coating lines give you a space-saving solution, causing them to be perfect for smaller production facilities or limited workspace. These lines are created to be efficient and versatile, allowing manufacturers to coat a variety of fiber optic cables with precision. However, due to their compact size, they might have slightly lower production capacity in comparison to full-scale coating lines.

Around the other hand, full-scale coating lines are designed for larger production volumes and may handle a diverse selection of cable sizes and specifications. They supply high-speed coating capabilities, enabling manufacturers to fulfill demanding production targets. However, full-scale coating lines require more floor space and may involve an increased initial investment.

Here’s a simple comparison of these two types:

| Compact Coating Lines |

Full-Scale Coating Lines |

| Space-saving solution |

Ideal for larger production volumes |

| Versatile and efficient |

High-speed coating capabilities |

| Suitable for smaller production facilities |

Require more floor area |

| Could have slightly lower production capacity |

Higher initial investment |

When picking between compact and full-scale coating lines, manufacturers should look into their production requirements, available space, and investment capabilities. Both options can deliver quality coating results, but the choice ultimately is dependent upon the precise needs and goals from the production facility.

Maximizing Production With Higher-Speed Secondary Coating

Methods For Increasing Line Speeds

In terms of fiber optic cable production, maximizing production efficiency is really a top priority. One way to do this is actually by implementing high-speed secondary coating technology. By increasing line speeds in the coating process, manufacturers can significantly improve overall productivity and meet the growing need for fiber optic cables.

To boost line speeds, several strategies can be employed. Firstly, optimizing the coating materials and formulations can help reduce cure time, permitting faster processing. Secondly, implementing advanced machinery and automation systems can enhance the speed and efficiency of the coating process, minimizing production bottlenecks. Leveraging state-of-the-art equipment specifically designed for high-speed secondary coating can create a significant difference in line speeds and productivity.

Furthermore, streamlining the workflow and minimizing manual interventions is able to reduce downtime and improve throughput. By utilizing efficient material handling systems and implementing lean manufacturing principles, manufacturers can minimize material waste and achieve higher production speeds without compromising on quality.

Reducing Downtime and Material Waste

Reducing downtime is crucial for maximizing production efficiency in high-speed secondary coating. Any unplanned interruptions can lead to significant losses in productivity and increased material waste. To minimize downtime, proactive maintenance and regular equipment inspections ought to be conducted to distinguish and address potential issues before they cause production stoppages.

Furthermore, implementing efficient changeover procedures will help reduce downtime during product transitions. By optimizing the setup and cleaning processes between different cable types or coating materials, manufacturers can minimize downtime and maximize production time.

Material waste is yet another aspect that requires careful management in high-speed secondary coating. By closely monitoring and managing the coating application parameters, manufacturers can minimize excess material usage and improve material efficiency. Implementing automated systems for precise material dispensing and coating thickness control may help optimize material usage and lower waste.

Managing Excess Fiber Length in High-Speed Environments

Managing excess fiber length in high-speed secondary coating environments can present challenges for manufacturers. Excess fiber length can lead to tangling, snags, or inconsistent coating coverage, affecting product quality and gratification. To effectively manage excess fiber length, manufacturers can implement advanced fiber tension control systems that ensure smooth and continuous fiber movement through the coating process.

Automated monitoring and feedback systems can help detect and correct any deviations in fiber length, ensuring consistent coating application and high-quality end products. Additionally, deploying advanced fiber laying techniques, such as controlled fiber looping, may help manage excess fiber length and ensure uniform coating coverage, reducing the chance of performance issues.

By leveraging high-speed secondary coating technology and implementing approaches to increase line speeds, reduce downtime, minimize material waste, and manage excess fiber length, manufacturers can maximize production efficiency and fulfill the growing need for fiber optic cables.

| Techniques for Maximizing Production Efficiency in High-Speed Secondary Coating |

| Implement high-speed secondary coating technology |

| Optimize coating materials and formulations |

| Utilize advanced machinery and automation systems |

| Streamline workflow and minimize manual interventions |

| Proactively maintain equipment and conduct regular inspections |

| Implement efficient changeover procedures |

| Monitor and control coating application parameters |

| Implement automated systems for precise material dispensing and coating thickness control |

| Implement advanced fiber tension control systems |

| Deploy automated monitoring and feedback systems |

| Utilize controlled fiber looping techniques |

Enhancing Quality Control in Fiber Coating Processes

In the creation of fiber optic cables, quality control is extremely important to make certain consistent and-quality coating. Fiber coating processes play a crucial role in protecting the delicate glass fiber core and looking after optimal performance in different environments. To achieve these objectives, rigorous testing and inspection through the coating process are necessary.

There are various methods and technologies utilized to boost the quality control in fiber coating processes. Laser measurement systems, for instance, provide precise power over the thickness and uniformity of the coating, ensuring optimal optical properties. Additionally, automated inspection tools with advanced imaging capabilities enable thorough visual inspection to detect any defects or imperfections inside the coating.

Quality control is crucial in fiber coating methods to keep up with the performance and reliability of fiber optic cables. By implementing robust testing and inspection methods, manufacturers can ensure consistent and high-quality coating, enhancing the overall excellence of the final product.

Another important aspect of quality control in fiber coating processes is the adherence to industry standards and specifications. Manufacturers must follow guidelines set by organizations like the International Electrotechnical Commission (IEC) to make sure that the coating materials and procedures satisfy the required performance criteria.

Using statistical process control (SPC) techniques can also contribute to effective quality control in fiber coating. SPC allows manufacturers to keep track of the coating process in real-time, detect any deviations through the desired parameters, and make immediate changes in maintain consistency and quality.

By implementing comprehensive quality control measures, manufacturers can optimize the fiber coating processes, making sure the final fiber optic cables fulfill the highest standards of performance, reliability, and sturdiness.

Insights into Fiber Draw Tower Mechanics and Functionality

In the manufacturing procedure of fiber optic cables, SZ stranding line play a vital role in producing high-quality fibers. Understanding the mechanics and functionality of these towers is essential for optimizing fiber quality and overall cable performance.

Understanding Draw Tower Operation

The draw tower operation necessitates the precise charge of tension and speed to elongate and strengthen the fiber. The process begins with a preform, which is heated and drawn through a series of dies to reduce its diameter. The fiber will then be coated having a secondary layer for protection against external factors.

The draw tower provides for continuous production, with all the fiber being drawn at high speeds. The tension control system ensures uniform fiber quality, minimizing variations in diameter and enhancing mechanical strength.

Integrating Coating Technology Into the Draw Process

To advance enhance fiber quality, coating technology is integrated into the draw process. By using a secondary coating, the fiber remains safe and secure from moisture, temperature variations, and mechanical stress. This coating helps maintain optimal fiber performance and ensures long-term reliability.

The integration of coating technology to the draw process requires precise control of the coating application, ensuring uniform thickness and complete coverage. Advanced coating systems are utilized to achieve accurate and consistent results.

Draw Tower Innovations for Better Fiber Quality

Ongoing innovations in draw tower technology have triggered significant improvements in fiber quality. A few of the key innovations include:

- Advanced Tension Control: Modern draw towers are equipped with advanced tension control systems which allow precise and automated control over fiber tension. This ensures consistent fiber quality and reduces the potential risk of breakage through the drawing process.

- Online Monitoring Systems: Draw towers now feature online monitoring systems that continuously monitor and analyze various parameters, like fiber diameter, coating thickness, and tension. This real-time feedback enables immediate adjustments, ensuring optimal fiber quality.

- Process Automation: Automation technologies have been incorporated into draw towers, reducing manual intervention and improving production efficiency. Automated systems control the complete fiber drawing process, minimizing human error and optimizing fiber quality.

- Innovative Die Designs: The design in the drawing dies has changed, allowing for precise control of fiber dimensions and enhanced fiber strength. Innovative die materials and coatings contribute to better fiber quality and reduced downtime.

By including these innovations, fiber draw towers are able to produce fibers of exceptional quality, meeting the stringent requirements of contemporary fiber optic cable production.

| Innovation |

Benefits |

| Advanced Tension Control |

Ensures consistent fiber quality and reduces breakage |

| Online Monitoring Systems |

Allows for real-time adjustments and optimal fiber quality |

| Process Automation |

Reduces manual intervention and optimizes production efficiency |

| Innovative Die Designs |

Enables precise control over fiber dimensions and enhanced strength |

FTTH Cable Production: Emphasizing Precision and Efficiency

Within the fast-paced world of fiber optic cable manufacturing, the creation of FTTH (Fiber towards the Home) cables needs a special emphasis on precision and efficiency. Because the need for high-speed internet connectivity consistently surge, it is crucial to ensure the manufacturing process meets the stringent requirements and standards of FTTH cable production.

Producing FTTH cables involves intricate processes which require precise control and efficient workflows to deliver high-quality cables that will fulfill the increasing bandwidth demands of recent households. This can include the deployment of advanced technologies and automated systems to streamline production, minimize errors, and optimize efficiency.

By including precision technologies and automated systems, manufacturers can achieve greater accuracy in cable dimensions, connector compatibility, and fiber alignment, leading to improved performance and reliability. This amount of precision is vital to make sure that FTTH cables can deliver fast and reliable internet connectivity to homes.

Efficiency is an additional fundamental element of FTTH cable production. By implementing efficient workflows and optimized manufacturing processes, manufacturers can increase productivity and reduce waste, ultimately resulting in higher output and expense savings. Efficiency is particularly essential in meeting the growing global interest in fiber optic cables and ensuring that the production process keeps with market requirements.

Through continuous innovation and investment in state-of-the-art equipment, the market is maximizing the precision and efficiency of FTTH cable production. This enables manufacturers to provide high-performance and reliable cables, empowering homes with fast and reliable internet connectivity for that modern digital age.

The Role of Sheathing Lines in Fiber Optic Cable Construction

Sheathing lines play a vital role in the making of fiber optic cables, providing essential external protection to make certain optimal performance and longevity. Through the entire process of sheathing, fiber optic cables are shielded from environmental factors, mechanical stress, along with other potential damage.

Adding External Protection through Sheathing

Sheathing serves as a protective layer around the fiber optic cables, safeguarding them from moisture, UV radiation, temperature fluctuations, and physical impact. This external protection is crucial in maintaining the integrity of the cables, preventing signal loss, and ensuring reliable transmission in even the harshest conditions.

Customizable Sheathing Solutions For Many Different Cable Types

With an array of cable types and applications, customized sheathing solutions are necessary to satisfy the precise requirements of numerous projects. Whether it’s indoor or outdoor cables, aerial or underground installation, or specialized industrial applications, sheathing lines provide you with the flexibility to tailor the protective layer according to the specific needs in the cables.

Customizable sheathing solutions might include materials with varying thicknesses, compositions, and mechanical properties to match the preferred level of protection and durability. This customization enables optimal performance and longevity in diverse environments and applications.

Automated Sheathing Systems for Consistent Quality

To guarantee consistent quality and efficiency in the sheathing process, automated sheathing systems are becoming indispensable in modern fiber optic cable construction. These systems utilize advanced technology and precision machinery to apply the protective sheathing layer accurately and consistently.

Automated sheathing systems offer numerous advantages, including increased production speed, reduced human error, and improved overall product quality. With automated control and monitoring, these systems can maintain precise parameters through the entire sheathing process, causing consistent and reliable cable performance.

By leveraging customizable sheathing solutions and automated sheathing systems, fiber optic cable manufacturers can effectively protect their cables from external factors and deliver high-quality, reliable products to meet the ever-increasing demands from the telecommunications industry.

Conclusion

In Conclusion, the implementation of fiber secondary coating line technology plays a crucial role in optimizing fiber optic cable production. Throughout this article, we have now explored the importance of secondary coating in fiber optic cables. It behaves as a protective layer that safeguards the delicate glass fiber core, ensuring its durability and reliability even during harsh environments.

By sustaining optimal optical properties, such as low attenuation and signal transmission quality, secondary coating technology guarantees the efficient operation of fiber optic cables. It enhances their performance and longevity, causing them to be suitable for a variety of applications.

Furthermore, we have now discussed the advancements in fiber optic cable coating solutions, including using innovative materials and new coating techniques. These advancements have resulted in enhanced protection and improved performance. The accessibility of custom coating systems tailored to specific cable specifications further enhances the versatility in the production process.

Since the interest in fiber optic cables continues to grow, the main focus on cost efficiency in manufacturing becomes imperative. By leveraging high-speed secondary coating, strategies may be implemented to boost line speeds, reduce downtime, and minimize material waste. This, subsequently, maximizes production output and ensures optimal utilization of resources.

In conclusion, fiber secondary coating line technology is a key component in fiber optic cable production. Its significance cannot be understated, because it contributes to the overall quality, performance, and cost efficiency from the cables. By using state-of-the-art equipment and embracing innovative coating solutions, manufacturers can elevate their production processes and deliver reliable and high-performing fiber optic cables to satisfy the ever-growing connectivity needs of numerous industries.